If you recall in the previous post, the Corbeau FX1 Pro seats are much too high, especially with the seat padding in. Big ups to Dan from Assaultech for contacting Corbeau for me on this trick here. Apparently you can remove the rear feet from the seats for better fitment/extra headroom. Corbeau specified to remove the rear feet only, and to remove up to 3/4'. Thing is, 3/4' is pretty much the entire rear foot, measured from the smallest point of the foot. Big ups to Shane for his lumber jacking of the feet all night. We used a six inch hack saw to cut them off, while using a filer to round off any edges if need be. If we were to do it again though... Shane says Reciprocating saw or a sawsall.

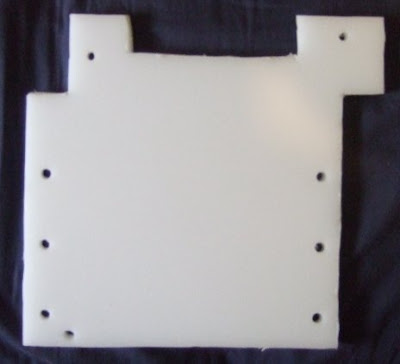

If you recall in the previous post, the Corbeau FX1 Pro seats are much too high, especially with the seat padding in. Big ups to Dan from Assaultech for contacting Corbeau for me on this trick here. Apparently you can remove the rear feet from the seats for better fitment/extra headroom. Corbeau specified to remove the rear feet only, and to remove up to 3/4'. Thing is, 3/4' is pretty much the entire rear foot, measured from the smallest point of the foot. Big ups to Shane for his lumber jacking of the feet all night. We used a six inch hack saw to cut them off, while using a filer to round off any edges if need be. If we were to do it again though... Shane says Reciprocating saw or a sawsall.If you are doing this mod yourself to your own set of Corbeau FX1 Pro seats, take a look around the seat for the smaller bolts that allow you to side mount the seat. I used those smaller bolts for the rear pegs, as the normal bolts would protrude the bottom of the seat, and would be quite hard to sit down or even use the cushion.

Once we did this modification, the seats were a perfect height. Without the cushions, I sat a touch lower than stock, while with the cushions I sat just a touch higher than stock. I will still need to take out the seat cushions to fit my helmet perfectly, but I can have them in and be comfortable while driving on the street. honestly, I wish the seats came from Corbeau with this height difference as the seat feels much more comfortable with the slight lean, cradling the driver comfortably, along with the extra headroom is always a plus.

Some quick pictures of the cutting in action.